Special Type Induction Heater

Price 50000-200000 INR/ Piece

Special Type Induction Heater Specification

- Voltage

- 380 V / 50 Hz

- Rated Frequency

- 50/60 Hz

- Type

- Special Type Induction Heater

- Material

- High Grade Alloy & Steel

- Application

- Industrial Heating, Shrink Fitting, Hardening, Annealing, Brazing

- Max. Input Power

- 12 kW

- Max. Output Power

- 10 kW

- Oscillation Frequency

- 15~30 kHz

- Cooling Water Pressure

- 0.2 MPa

- Host Weight

- 32 kg

- Transformer Weight

- 23 kg

- Temperature Protection

- Yes

- Max Output Current

- 400 A

- Ambient Temperature

- 0~50°C

- Cooling Mode

- Water Cooling

- Control Mode

- Microcomputer Digital Control

- Input Phase

- Three Phase

- Duty Cycle

- 100%

- Power Factor

- >0.9

Special Type Induction Heater Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Special Type Induction Heater

Item Code: PIH-SPL 2001 - 2002 - 2003Precision induction heater is available as Model PIH-SPL .

The features of our induction heaters are:

- Swing arm arrangement

- Boost Up facities

- Heating job of 300 Kg.

Robust Industrial Design

Constructed from high-grade alloy and steel, this induction heater offers durability and superior performance even in rigorous industrial settings. Its water cooling system enables continuous operation, while efficient microcomputer controls provide precise temperature adjustments for various applications such as hardening, brazing, or shrink fitting.

Smart Digital Control System

The microcomputer digital control mode ensures accurate monitoring and easy adjustment of heating parameters. This not only improves operational consistency but also enhances safety through its integrated temperature protection mechanism. The digital interface makes the system intuitive for technicians and operators alike.

Versatile Application Range

Ideal for multiple industrial uses, this induction heater serves in processes like annealing, hardening, brazing, and shrink-fitting. The adjustable oscillation frequency and powerful output make it suitable for both large-scale manufacturing and specialized tasks, adapting seamlessly to different heating requirements.

FAQs of Special Type Induction Heater:

Q: How does the water cooling mode benefit the induction heaters performance?

A: The water cooling mode ensures that the induction heater can operate continuously at full load (100% duty cycle) without overheating. This maintains stable performance, extends equipment lifespan, and allows for efficient heat dissipation during demanding industrial applications.Q: What is the process for using the microcomputer digital control system?

A: The microcomputer digital control system provides an easy-to-use interface for adjusting heating parameters such as output power and frequency. Operators can set specific heating profiles, monitor temperatures in real time, and benefit from automatic temperature protection, ensuring safe and precise operation.Q: When is this special type induction heater most effectively utilized?

A: This heater is especially effective in applications like industrial heating, shrink fitting, hardening, annealing, and brazing where precise and reliable thermal processing is required. It is suitable in environments requiring continuous operation and strict process control.Q: Where can this induction heating system be installed?

A: The system is designed for industrial use and should be installed in manufacturing facilities or workshops where three-phase 380 V / 50 Hz power supplies are available. Proper access to a water supply for cooling (at 0.2 MPa pressure) is also essential for optimal operation.Q: What are the key benefits of choosing this induction heater for industrial tasks?

A: Key benefits include high energy efficiency (power factor >0.9), continuous operation capability (100% duty cycle), precise digital control, robust materials, temperature safety features, and adaptability to a variety of industrial heating processes.Q: How is ambient temperature important for the operation of this heater?

A: The heater is designed to function efficiently within an ambient temperature range of 0 to 50C. This ensures reliable performance across a variety of industrial environments, provided the ventilation and cooling water requirements are met.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Heater Category

Induction Heater For Removal

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380V / 50Hz

Material : Stainless Steel, Copper Coil

Type : Portable Induction Heater

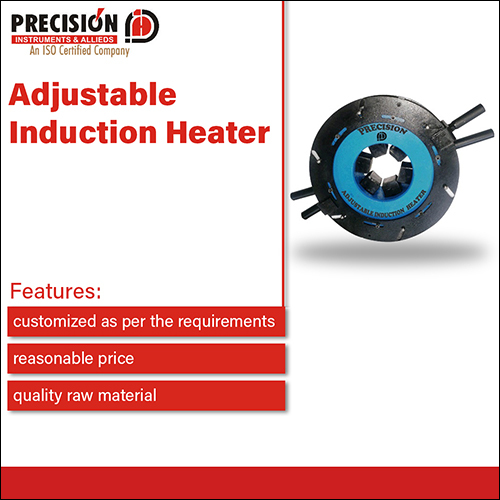

Adjustable Induction Heater

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 V

Material : Mild Steel

Type : Adjustable Induction Heater

Industrial Induction Heater

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 V

Material : Mild Steel

Type : Industrial Induction Heater

Precision Induction Heater

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220V / 380V AC

Material : Mild Steel Body

Type : Precision Induction Heater

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free