Industrial Induction Heater

Industrial Induction Heater Specification

- Voltage

- 380 V

- Rated Frequency

- 50/60 Hz

- Type

- Industrial Induction Heater

- Material

- Mild Steel

- Application

- Shrink Fitting, Hardening, Brazing, Soldering, Annealing

- Max. Input Power

- 35 kW

- Max. Output Power

- 30 kW

- Host Weight

- 48 kg

- Transformer Weight

- 38 kg

- Temperature Protection

- Yes

- Cooling Method

- Water Cooling

- Input Phase

- Three Phase

- Ambient Temperature

- 5C to 40C

- Duty Cycle

- 100%

- Overload Protection

- Available

- Control Mode

- Digital Display

- Heating Efficiency

- Above 90%

- Power Adjustment

- Stepless Adjustment

- Relative Humidity

- 90%

Industrial Induction Heater Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Industrial Induction Heater

Model: PIH 2003

To cater to the variegated requirements of different industries, we are involved in offering Industrial Induction Heater. It is accurately designed and manufactured with qualitative components under the supervision of our well-trained professionals. Offered induction heater weighs about 95 Kg and integrated with advanced micro-controller based electronic control that makes its operations highly user-friendly. Suitable for generating temperature up to 100 degree centigrade within 6 to 7 minutes, Industrial Induction Heater is demanded by customers for its capability to heat bearings of 300 Kg to 320 Kg.

Other details:

Model PIH 2003 is provided with manual or automated Roll-sliding Arrangement for the standard yoke 80x80x550 mm. The Roll-Sliding Arrangement is so designed that the yoke gets lifted mechanically or automatically rolls off from the vertical supports without rubbing or damaging and scraping mating surfaces. This arrangement provides additional safety, ease of operation and helps to improve productivity.

| Sr. | PRODUCT DATA | PIH - 2003 |

| 1) | Diameter (mm) Bearing | 60 to 600 |

| 2) | Bearing Weight | 300 Kg |

| 3) | Power | 12 / 16 KVA |

| 4) | Voltage | 440V |

| 5) | Power Control | 25%, 50%, 75%, & 100% |

| 6) | Temperature Control (Range) | 0 - 250oC |

| Maximum Temperature | 400oC | |

| Accuracy Temperature | 3oC | |

| 7) | Time - Control | 0 - 99 Minutes |

| 8) | Residual Magnetism | <2A / cm |

| 9) | Overall dimensions (wxdxh) (mm) | 800 x 530 x 590+ |

| 10) | Space between supports (wxh) (mm) | 310 x 255 |

| 11) | Weight (Main Unit) | 95 Kg. |

| 12) | Weight with Standard Yokes | 125 Kg. |

| 13) | Horizontal Yoke Sizes (mm) | 80 x 80x 550 |

| --------- | ||

| --------- | ||

| 14) | Can Heat Sealed & Pre-greased Bearings | |

| 15) | Thermal Over Protection |

| Sr. | Optional Accessories | |

| 1) | Horizontal Yoke Sizes (mm) | 30 x 30 x 550 |

| 40 x 40 x 550 | ||

| 50 x 50 x 550 | ||

| 70 x 70 x 550 | ||

| 2) | Digital Thermometer (0-500oC) | |

| 3) | Roll - Sliding Model | |

| 4) | Swing Arm Model | |

| 5) | Riser Block (Pair) (mm) | |

| 6) | Magnetic Temperature Probe | |

| 8) | Equipment Trolley | |

We reserve the right to change the specifications without prior notice.

Advanced Digital Control for Precision

Our induction heater incorporates an intuitive digital display, allowing users to efficiently monitor and manage heating parameters. This ensures precise temperature control and maintains optimal processing conditions for various industrial tasks. The easy-to-navigate interface enhances user productivity and reduces the margin for operational error, supporting consistent high-quality results.

Robust Efficiency and Reliable Safety

Engineered with a 100% duty cycle and a heating efficiency above 90%, this device is tailored for continuous heavy-duty operations. It features comprehensive overload and temperature protection systems, guarding against operational risks and maximizing equipment lifespan. Water cooling further assures stable temperature regulation during persistent industrial use.

FAQs of Industrial Induction Heater:

Q: How can I adjust the power settings on this induction heater?

A: The induction heater features stepless power adjustment, allowing you to fine-tune the output precisely using the digital display controls. This flexibility enhances suitability for various processes, including shrink fitting, hardening, brazing, soldering, and annealing.Q: What are the main benefits of using water cooling in this system?

A: Water cooling efficiently manages heat buildup during continuous operation, supporting the heaters 100% duty cycle. This maintains optimal performance, increases the units lifespan, and reduces risk of overheating during prolonged industrial applications.Q: When should overload and temperature protection be utilized?

A: Overload and temperature protection operate automatically to safeguard the unit during high-demand periods or if temperature thresholds are exceeded. This feature provides peace of mind for industrial users by preventing equipment damage and minimizing downtime.Q: Where is this induction heater typically used?

A: This industrial heater is ideal for factories and workshops requiring precise heat treatment, such as in manufacturing, metalworking, and engineering industriesspecifically for shrink fitting, hardening, brazing, soldering, and annealing tasks.Q: What process steps are involved in using this heater for shrink fitting applications?

A: First, set the desired temperature via the digital display and adjust the power output as needed. Place the component to be heated in the induction coil, and initiate the process while monitoring on the screen. The water cooling system will maintain optimal conditions throughout.Q: How does the high heating efficiency benefit industrial operations?

A: With a heating efficiency above 90%, energy is converted effectively to heat, reducing electricity consumption, minimizing waste, and accelerating process cycles, thereby increasing overall productivity and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Heater Category

Special Type Induction Heater

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : High Grade Alloy & Steel

Voltage : 380 V / 50 Hz

Type : Special Type Induction Heater

Pinion Induction Heater

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Voltage : 380V

Type : Pinion Induction Heater

Industrial Induction Heater PIH 2001 (3.5/4.0 KVA)

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Voltage : 230 Volt (v)

Type : Induction Heater

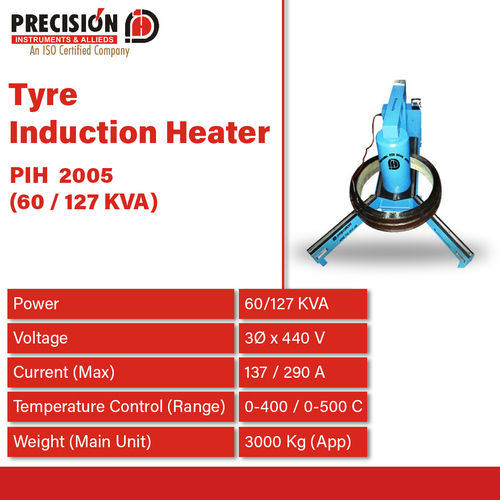

Induction Tyre Heater

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Voltage : 440 Volt (v)

Type : Induction Tyre Heater

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS