Intelligent induction heater

Intelligent induction heater Specification

- Type

- Intelligent Induction Heater

- Material

- Stainless Steel & High Quality Components

- Application

- Metal Heat Treatment, Brazing, Shrink Fitting, Annealing, Soldering

- Max. Input Power

- 35 kW

- Max. Output Power

- 30 kW

- Host Weight

- 32 kg

- Transformer Weight

- 25 kg

- Temperature Protection

- Up to 85C

Intelligent induction heater Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Intelligent induction heater

Ours is a reliable firm, engaged in manufacturing and supplying Intelligent induction heater. It is manufactured with qualitative components incorporating sophisticated technology so as to ensure its durability, hassle-free performance & robust construction. This induction heat is widely used for mounting & dismounting the inner races of cylindrical roller bearings that are used on axles of railway rolling stock as well as in traction motors. Owing to its intelligent micro-controller based electronic controls, it proves highly user-friendly. Offered Intelligent induction heater is acclaimed by our clients for its high efficiency, low power consumption and easy installation.

Other details:

PIR Series Intelligent Precision Induction Heater is fast, safe, and there is economical heating of cylindrical roller bearings inner races. It gets strong magnetism to attract iron dust and iron particles etc. when an element is heated with the induction coil. To deal with this process, it is essential to remove the residual magnetism after heating. The unique design of control panel of precision Induction Heater Model - PIR 40 allows quick demagnetization with the heating coil itself. The Induction Coil is used for both demagnetization and heating.

Product Features:

- High heating rates can be easily achieved.

- Induction heating is more safe, reliable & clean process.

- Even unskilled labor can be trained to operate the equipment easily.

- Lower cost & high efficiency are the plus points of Induction Heating.

- Precise Temperature and Time controls are achieved through state of the art technology used in heaters.

- Can be used for Mounting 8. Dismounting of inner Race

- Safe, Reliable & Clean Process.

- Unskilled labour can be trained to operate.

- High Heating can be easily achieved.

- Lower cost 8. high efficiency.

- Precise Temperature and Time controls.

- Intelligent micro control based electronic controls

PRINCIPLE

When Alternating Current flows through a coil wound around a component; it creates an oscillating magnetic field, which includes current in the component. The magnetic field takes the path of least resistance and also due to the skin effect; the outer periphery of the component gets heated more rapidly than the core. Based on the above principle, a ring shrunk fitted on the shaft will get heated more rapidly causing a temperature differential between the two. The difference in the temperature will cause the ring to expand to a stage where it overcomes interference and can be dismounted easily.

| Product Data | PIR - 40 |

| Power | 40KVA |

| Supply Voltage | 3- 440V |

| Nominal Current | 90A |

| Output Voltage | 40 - 60V |

| Output Current | 800A |

| Power Control | 25%, 50%, 75%, 100% |

| Temperature Control | (0-250oC) |

| Accuracy Temperature | 5oC |

| Time Control | 0-2 min / 0-9.9min |

| Residual Magnetism | <2A/cm |

Advanced Technology for Metal Heat Treatment

This heater harnesses intelligent induction technology to achieve precise and uniform heating, optimizing results for processes like annealing and shrink fitting. Its control system ensures minimal energy wastage and consistent performance. The robust stainless steel construction further enhances longevity and resistance to harsh industrial settings.

Reliable Performance and Safety Features

With an impressive maximum input power of 35 kW and output of 30 kW, the heater accommodates heavy-duty tasks with ease. Integrated temperature protection up to 85C safeguards both the equipment and operators, reducing risks during extensive use. Its engineered to meet industrial safety and efficiency standards.

FAQs of Intelligent induction heater:

Q: How does an intelligent induction heater improve the metal heat treatment process?

A: The intelligent induction heater provides precise, rapid, and uniform heating, which enhances the quality and repeatability of metal heat treatment processes like brazing, annealing, and shrink fitting. Its smart controls minimize manual adjustments, resulting in greater operational efficiency.Q: What are the main benefits of using stainless steel and high-quality components in construction?

A: Utilizing stainless steel and premium components ensures the heater is highly resistant to corrosion, durable in industrial environments, and capable of withstanding frequent thermal cycles, thus prolonging the equipments lifespan.Q: When should I choose intelligent induction heating for my metalworking application?

A: Intelligent induction heating is ideal whenever precise temperature control, fast processing, and energy efficiency are requiredespecially in tasks such as soldering, annealing, and shrink fitting. It is also recommended for repetitive industrial heat treatment operations.Q: Where can this induction heater be used most effectively?

A: This heater is most effectively employed in manufacturing plants, repair workshops, and metal processing facilities where efficient, controlled heating for metal components is essential. Its suitable for exporters, suppliers, and manufacturers across India and beyond.Q: What is the process of operating this heater and what safety measures are included?

A: Operation involves setting the desired temperature and power levels on its control panel, monitoring the process, and allowing the systems intelligent mechanisms to regulate heating. The integrated temperature protection up to 85C offers an additional layer of safety, preventing overheating and equipment damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Heater Category

Adjustable Induction Heater

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Adjustable Induction Heater

Rated Frequency : 5060 Hz

Voltage : 380 V

Special Type Induction Heater

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Special Type Induction Heater

Rated Frequency : 50/60 Hz

Voltage : 380 V / 50 Hz

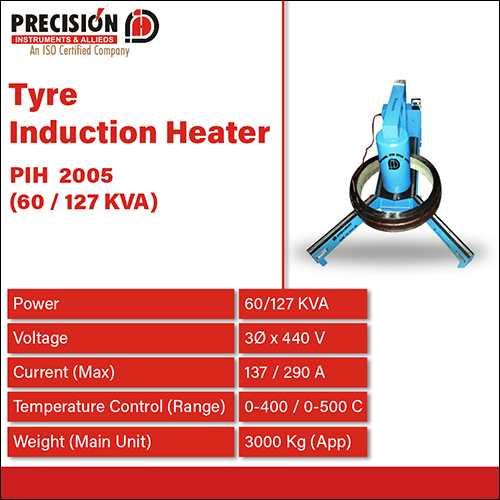

Induction Heater Model PIH 2005 60 127 KVA

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Induction Heater

Rated Frequency : 5060 Hertz (HZ)

Voltage : 440 Volt (v)

Precision Induction Heater

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Precision Induction Heater

Rated Frequency : 50Hz / 60Hz

Voltage : 220V / 380V AC

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS