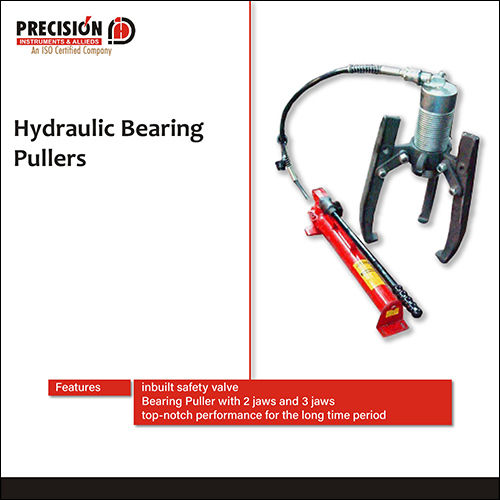

Hydraulic Bearing Pullers

Hydraulic Bearing Pullers Specification

- Operate Method

- Manual hand pump operated

- Used For

- Removing bearings, gears, pulleys and similar mechanical assemblies

- Length

- Varies according to model

- Product Type

- Hydraulic Bearing Puller

- Lift Design

- Hydraulic Mechanism

- Lifting Height

- Up to 350 mm (dependent on model)

- Width

- Varies as per model

- Lifting Capacity

- 5 to 100 tons (model dependent)

- Lifting Time

- Manual pump dependent

- Working Voltage

- Manual Operation

- Size

- Available in multiple capacities and arm lengths

- Power Source

- Manual Hydraulic

- Material

- Forged Steel Body

- Pressure Capacity

- Up to 700 Bar (model dependent)

- Color

- Blue & Black

Hydraulic Bearing Pullers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Hydraulic Bearing Pullers

Our firm is engaged in manufacturing and supplying a broad range of Bearing Pullers that are provided with 2 jaws and 3 jaws. These products are used for pulling bearings and other shrink-fit components maintaining their surface finish. Offered pullers are acclaimed by customers for their robust construction, easy installation, reliable operations and quality in tune with industry laid norms. Owing to these features, offered Bearing Pullers are widely used in maintenance and repair field.

Versatility in Application

Hydraulic Bearing Pullers are designed to adapt to multiple sizes, pressure needs, and mechanical tasks, including the removal of bearings, gears, and pulleys. The availability of various capacities and arm lengths makes them ideal for specialized workshops and large industrial operations alike.

Reliable and Durable Construction

Manufactured from high-grade forged steel, these pullers ensure long-lasting performance and safety. Their hydraulically-driven mechanism, powered by a manual hand pump, is engineered for consistent force distribution, minimizing risk of mechanical damage during use.

Ease of Manual Operation

These pullers utilize a manual hydraulic pump, requiring no electrical power source. The straightforward pump mechanism allows for precise control over lifting time and pressure, making them suitable for field operations and environments where power access is limited.

FAQs of Hydraulic Bearing Pullers:

Q: How do you operate a hydraulic bearing puller?

A: To operate a hydraulic bearing puller, position the arms securely around the part to be removed, ensuring proper alignment. Use the manual hand pump to deliver hydraulic pressure, which gradually increases the pulling force until the bearing, gear, or pulley is extracted safely from its seating.Q: What types of components can these pullers remove?

A: These pullers are suitable for removing a variety of mechanical assemblies, including bearings, pulleys, gears, and similar components found in industrial machinery and automotive equipment.Q: When should a hydraulic bearing puller be used instead of a conventional puller?

A: A hydraulic bearing puller should be chosen when dealing with large, tightly-fitted, or high-capacity assemblies where manual or conventional pullers might lack sufficient force, or where controlled, even pressure is critical to avoid component damage.Q: Where can I use these pullers effectively?

A: Hydraulic bearing pullers are widely applicable in manufacturing plants, repair workshops, automotive service centers, and even remote field locations due to their manual operation and portability.Q: What is the process for selecting the right puller model?

A: Choosing the appropriate model involves considering the size and capacity required for the task, the maximum lifting height needed, and the pressure capacity. Matching these parameters to your specific application ensures safe and efficient operation.Q: What are the primary benefits of using a manual hydraulic bearing puller?

A: Key benefits include portability, ease of operation, high power output for larger assemblies, and minimized risk of damage thanks to uniform hydraulic force. The manual mechanism also means no reliance on external power sources.Q: Are there different sizes and capacities available for various tasks?

A: Yes, these pullers come in multiple capacities ranging from 5 to 100 tons and offer different arm lengths and widths to suit a wide spectrum of mechanical assemblies and working environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Puller Category

CTRB Jack Type Puller

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Railway wheel shop and maintenance workshops

Product Type : Other, CTRB Jack Type Puller

Used For : Pulling and assembling Cartridge Taper Roller Bearings on axle journal

CTRB Puller Cum Installer

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Railway Workshop Equipment

Product Type : Other, CTRB Puller Cum Installer

Used For : Removing and installing Cartridge Taper Roller Bearings (CTRB) from Railway Axles

Inbuilt Pump Hydraulic Puller

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Inbuilt Pump Hydraulic Puller

Industrial Hydraulic Puller

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Other, Hydraulic Puller

Used For : Automobile

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free