CTRB Puller Cum Installer

CTRB Puller Cum Installer Specification

- Operate Method

- Remote Hydraulic Control

- Length

- 1020 mm

- Used For

- Removing and installing Cartridge Taper Roller Bearings (CTRB) from Railway Axles

- Product Type

- CTRB Puller Cum Installer

- Lift Design

- Hydraulic

- Lifting Height

- Up to 400 mm

- Width

- 520 mm

- Working Voltage

- 230 V AC, 50 Hz

- Motor Power

- 2 HP

- Power Source

- Electric

- Usage

- Railway Workshop Equipment

- Size

- Standard

- Material

- Alloy Steel

- Pressure Capacity

- 180 Bar (max)

- Color

- Yellow & Black

- Hydraulic Oil Requirement

- 20 litres (ISO VG 46 or equivalent)

- Cylinder Stroke

- 350 mm

- Packaging

- Export worthy, wooden case or as per client requirement

- Frame Construction

- Rugged welded steel frame for reliability

- Mobility

- Mounted on heavy duty wheels for easy movement

- Weight

- Approx. 450 kg

- Safety Features

- Overload protection, safety guards

- Maintenance

- Minimal, with easy access points

- Noise Level

- Less than 75 dB during operation

- Compliance

- Meets RDSO/ Railway standards

- Finish

- Powder coated for corrosion resistance

CTRB Puller Cum Installer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About CTRB Puller Cum Installer

Committed to quality and optimum customer satisfaction, our company is engaged in manufacturing and supplying CTRB Puller Cum Installer. Our professionals manufacture it with qualitative metals and check on different quality parameters to ensure its flawless working. Offered machine is acclaimed by our clients for its high efficiency, low maintenance, smooth movement, durability and quality as per industry laid norms. Our CTRB Puller Cum Installer is integrated with sophisticated motor which is highly energy efficient.

Mobility and Ease of Use

Featuring heavy-duty wheels, the CTRB Puller Cum Installer enables smooth and quick movement across railway workshops. Its remote hydraulic control allows operators to manage the device safely and efficiently, reducing manpower requirements and saving time.

Robust Performance & Reliability

With its welded steel frame and powder-coated finish, the machine promises excellent durability and corrosion resistance. Operating at up to 180 Bar hydraulic pressure and 2 HP motor power, it is built to handle heavy-duty tasks consistently while adhering to strict RDSO/Railway standards.

Enhanced Safety and Minimal Maintenance

This equipment is equipped with overload protection and safety guards, ensuring a high level of operator safety. Maintenance needs are minimal thanks to thoughtfully placed access points, lowering downtime and improving overall productivity in railway workshops.

FAQs of CTRB Puller Cum Installer:

Q: How is the CTRB Puller Cum Installer moved within the workshop?

A: The machine is mounted on durable, heavy-duty wheels, making it easy to maneuver across various areas in a railway workshop with minimal manual effort.Q: What is the primary use of this equipment in a railway setting?

A: It is designed specifically to remove and install Cartridge Taper Roller Bearings (CTRB) from railway axles, streamlining maintenance and repair processes in railway workshops.Q: When is maintenance required for the CTRB Puller Cum Installer?

A: Thanks to its minimal maintenance design and easy access points, routine maintenance can be scheduled as per workshop protocol or after a set number of operating hours, depending on usage intensity.Q: Where is this product commonly used?

A: This machine is commonly deployed in railway workshops, depots, and maintenance facilities where railway axles require servicing or CTRB changes.Q: What hydraulic oil is recommended for optimal performance?

A: The system operates best with 20 litres of ISO VG 46 hydraulic oil or an equivalent type, ensuring proper lubrication and hydraulic function.Q: How does the equipment ensure operator safety during use?

A: It features integrated overload protection and safety guards, limiting operational risks and safeguarding users throughout the hydraulic lifting and pressing process.Q: What are the benefits of using this CTRB Puller Cum Installer?

A: Key benefits include enhanced efficiency in CTRB removal and installation, easy mobility, robust safety features, low noise operation, and compliance with RDSO/Railway standards, making it ideal for demanding railway environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Puller Category

CTRB Jack Type Puller

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual Jack Operation

Size : Standard/Custom on request

Product Type : Other, CTRB Jack Type Puller

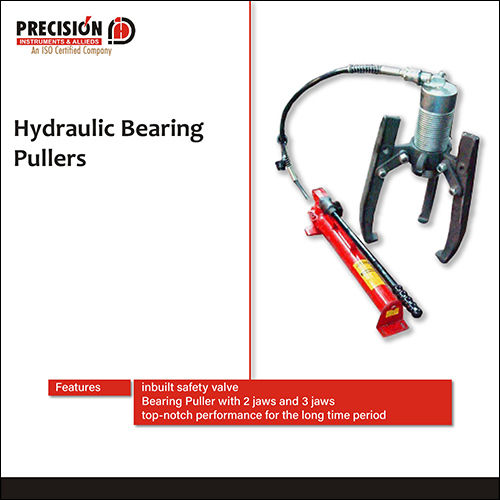

Hydraulic Bearing Pullers

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual hand pump operated

Size : Available in multiple capacities and arm lengths

Product Type : Other, Hydraulic Bearing Puller

Inbuilt Pump Hydraulic Puller

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual handle operated

Product Type : Other, Inbuilt Pump Hydraulic Puller

Industrial Hydraulic Puller

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Product Type : Other, Hydraulic Puller

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free