CTRB Jack Type Puller

Price 50000-200000 INR/ Piece

CTRB Jack Type Puller Specification

- Used For

- Pulling and assembling Cartridge Taper Roller Bearings on axle journal

- Operate Method

- Manual Jack Operation

- Length

- 650 mm

- Product Type

- CTRB Jack Type Puller

- Lift Design

- Mechanical Jack

- Lifting Height

- Up to 350 mm

- Width

- 175 mm

- Lifting Capacity

- Up to 10 Tons

- Lifting Time

- Approx. 1-2 minutes (manual)

- Lowering Time

- Approx. 1-2 minutes (manual operation)

- Working Voltage

- Manual Operation (No voltage required)

- Power Source

- Manual (Hand Operated)

- Usage

- Railway wheel shop and maintenance workshops

- Motor Power

- Not applicable (manual driven)

- Size

- Standard/Custom on request

- Color

- Orange/Custom epoxy finish

- Pressure Capacity

- Up to 10 Tons

- Material

- High-grade Alloy Steel

- Construction

- Heavy-duty robust welded frame

- Portability

- Portable, easy to move with handles

- Accessories Included

- Standard set of removal adapters supplied

- Customization

- Available on request

- Operating Temperature

- -10°C to +50°C

- Safety

- Designed with overload protection

- Application

- Designed for quick mounting and dismounting of CTRB

- Maintenance

- Low maintenance design

- Surface Finish

- Corrosion resistant, powder coated

CTRB Jack Type Puller Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About CTRB Jack Type Puller

Robust Performance for Railway Maintenance

Specifically designed for railway workshops, the CTRB Jack Type Puller offers a dependable solution for handling cartridge taper roller bearings on axle journals. Its robust welded frame and corrosion-resistant finish ensure longevity, while manual operation guarantees safety and control during use. The pullers mechanical jack allows for a lifting capacity of up to 10 tons, with a lifting height of up to 350 mm, making it ideal for demanding maintenance tasks.

Ease of Use and Portability

Thanks to its portable design, complete with easy-carry handles, this jack type puller can be conveniently relocated within your workshop or to different work sites. The supplied set of removal adapters enhances its versatility for various CTRB sizes. As a manual device, it operates efficiently with no power supply required, allowing for quick setup and operation in any environment.

Customizable and Low Maintenance Solution

The CTRB Jack Type Puller is engineered for trouble-free upkeep and minimal maintenance, reducing downtime in your workshop. Furthermore, customization options for size and finish are available upon request, letting you tailor the tool to meet unique operational requirements. Its bright epoxy finish further reinforces its resistance to corrosion and energetic workshop activities.

FAQs of CTRB Jack Type Puller:

Q: How is the CTRB Jack Type Puller used in railway maintenance workshops?

A: The puller is manually operated to quickly mount and dismount cartridge taper roller bearings (CTRB) on axle journals, making it an essential tool for railway wheel shops and maintenance tasks.Q: What benefits does the heavy-duty welded frame and corrosion-resistant finish provide?

A: The strong welded frame ensures reliable performance under heavy loads, while the powder-coated, corrosion-resistant finish extends the tools lifespan and reduces maintenance needs.Q: When should I use the supplied removal adapters?

A: Use the standard set of removal adapters whenever you need to accommodate different CTRB sizes during mounting or dismounting processes, ensuring a secure and precise fit each time.Q: Where can this jack type puller be utilized most effectively?

A: It is most effective in railway wheel shops, locomotive maintenance workshops, and industrial settings where cartridge taper roller bearings are frequently assembled or removed.Q: What is the advantage of the pullers manual operation and portability?

A: Manual operation provides independence from electricity, making the tool usable in remote locations. Its portabilitythanks to integrated handlesadds convenience for relocating within or between workshops.Q: Can the CTRB Jack Type Puller be customized for my specific needs?

A: Yes, customization options are available for size and finish upon request, so the puller can be tailored to your specific operational requirements.Q: How does overload protection enhance safety during operation?

A: Overload protection ensures the tool does not exceed its rated 10-ton capacity, minimizing risk of damage or injury during heavy-duty bearing removal or assembly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Puller Category

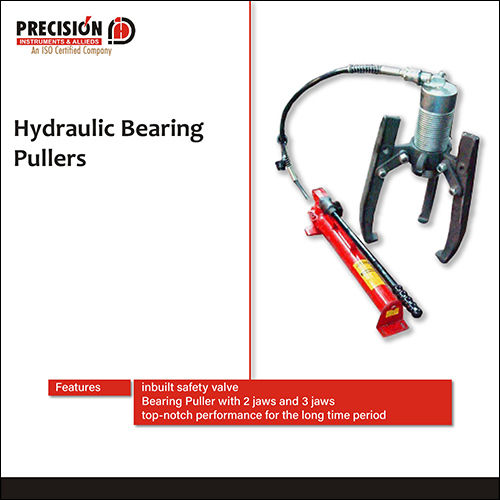

Hydraulic Bearing Pullers

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Removing bearings, gears, pulleys and similar mechanical assemblies

Operate Method : Manual hand pump operated

Product Type : Other, Hydraulic Bearing Puller

CTRB Puller Cum Installer

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Removing and installing Cartridge Taper Roller Bearings (CTRB) from Railway Axles

Operate Method : Remote Hydraulic Control

Product Type : Other, CTRB Puller Cum Installer

Inbuilt Pump Hydraulic Puller

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Manual handle operated

Product Type : Other, Inbuilt Pump Hydraulic Puller

Industrial Hydraulic Puller

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Automobile

Product Type : Other, Hydraulic Puller

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free