Manual Hydraulic Stackers

Manual Hydraulic Stackers Specification

- Rotation Type

- Fixed Forks

- Forklift

- Not Included

- Wheel Type

- Nylon/Cast Iron

- Handle Type

- Powder Coated, Ergonomic

- Control System

- Manual Control

- Lifting Speed

- Manual, Depends on Operator

- Equipment Type

- Manual Hydraulic Stacker

- Condition

- New

- Lifting Capacity

- 1000 kg

- Max. Lifting Load

- 1000 kg

- Max. Lifting Height

- 1600 mm

- Power Source

- Manual Hydraulic

- Power Consumption

- Manual Operation, No Electric Power

- Feature

- Easy Lifting and Lowering

- Attributes

- Heavy Duty, Portable

Manual Hydraulic Stackers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Manual Hydraulic Stackers

Key Features:

- Excellent capacity and lifting height

- Rigid in construction & silent in operation

- Easy to use, hydraulically operated

- Low operating & maintenance cost

- Light, compact, versatile & mobile

Effortless Manual Hydraulic Lifting

This stacker uses a high-quality manual hydraulic mechanism, granting users complete control over lifting and lowering heavy loads up to 1000 kg. Its operation is smooth and precise, allowing for managed handling without any need for external power sources. The ergonomic handle provides comfort, ensuring that repeated use remains easy and efficient for operators in fast-paced industrial environments.

Highly Portable and Versatile

Designed for portability, the manual stacker features a compact frame and durable wheels, making movement between workstations seamless. Its heavy-duty construction and fixed fork design make it suitable for a wide range of load sizes, allowing businesses to maximize productivity without investing in bulky powered equipment. This flexibility makes it an essential tool for dynamic warehousing and material handling tasks.

FAQs of Manual Hydraulic Stackers:

Q: How do you operate the manual hydraulic stacker for lifting and lowering loads?

A: Operation is straightforward: use the ergonomic, powder-coated handle to pump the hydraulic system and raise the forks. To lower, a simple manual release lever provides smooth, controlled descent, allowing for precise positioning of goods.Q: What are the main benefits of using a manual hydraulic stacker over electric alternatives?

A: Manual hydraulic stackers require no electricity, reducing power costs and allowing usage even in areas without a power supply. They are also easier to maintain, highly portable, and offer dependable heavy-duty performance for frequent lifting tasks.Q: Where is this manual hydraulic stacker best utilized?

A: This stacker is ideal for warehouses, production facilities, and loading docks, or any setting where lifting and moving heavy items is needed but electrical connectivity may be limited. Its portable design enables use throughout diverse industrial environments in India.Q: When should you choose a manual hydraulic stacker instead of a forklift?

A: Choose a manual hydraulic stacker when your operations involve medium-load lifting, tight maneuvering spaces, or a need for low-maintenance equipment. It is particularly fitting when electric forklifts are impractical or unnecessary for the workload.Q: What process should you follow for safe and effective use of the stacker?

A: Always inspect the stacker for any wear or faults before use. Make sure your load does not exceed the 1000 kg maximum. Use the manual controls steadily to lift or lower items and move the equipment using the robust nylon or cast iron wheels.Q: How does the manual operation affect power consumption?

A: Power consumption is eliminated as the stacker operates using manual hydraulic force alone, making it cost-effective and environmentally friendly while simplifying maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Stacker Category

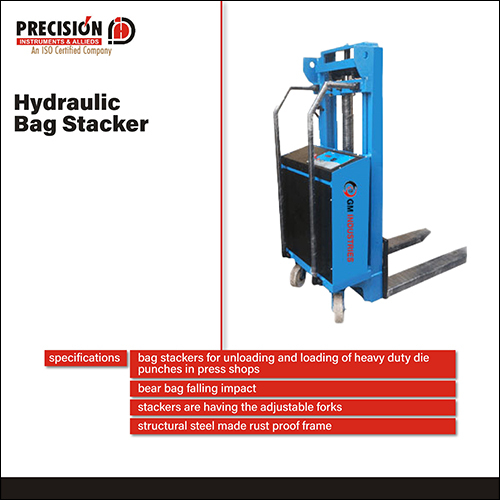

Hydraulic Bag Stacker

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosion Resistant, Userfriendly controls

Equipment Type : Hydraulic Bag Stacker

Condition : New

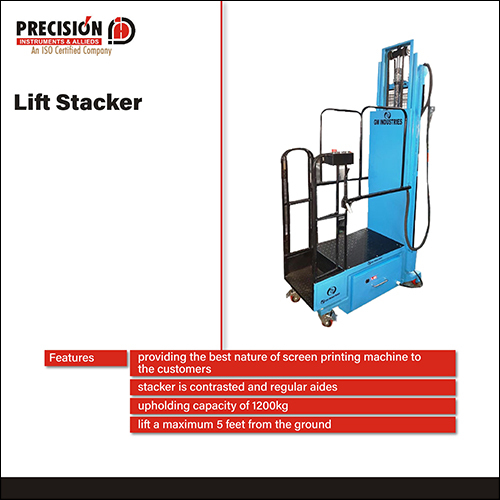

Lift Stacker

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Compact, Efficient, Low maintenance

Equipment Type : Manual Lift Stacker

Condition : New

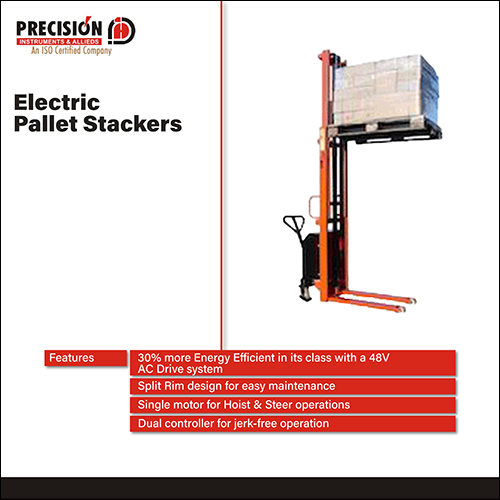

Electric Pallet Stacker

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Emergency Stop Button, Compact Design, Maintenance Free Battery

Equipment Type : Electric Pallet Stacker

Condition : New

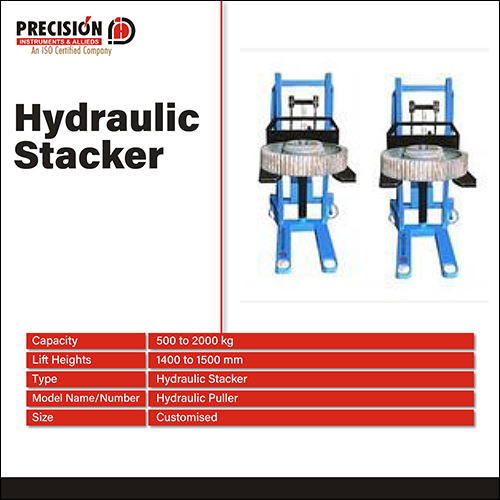

Industrial Hydraulic Stackers

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust Construction, Compact Design

Equipment Type : Industrial Hydraulic Stacker

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free