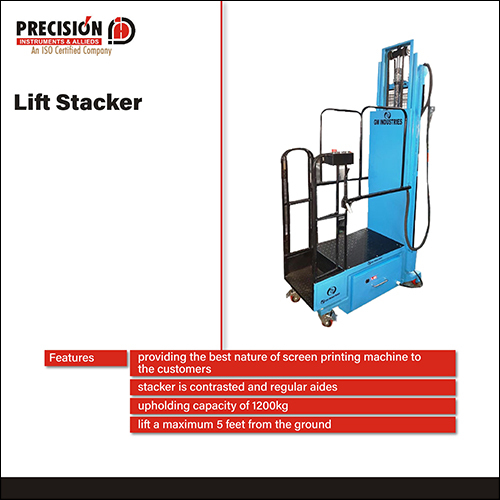

Lift Stacker

Lift Stacker Specification

- Features

- Compact, Efficient, Low maintenance

- Forklift

- No

- Control System

- Manual Hydraulic

- Rotation Type

- Fixed Mast

- Handle Type

- Ergonomic Push Handle

- Equipment Type

- Manual Lift Stacker

- Motor Type

- No Motor (Manual)

- Wheel Type

- Nylon/PU Wheels

- Rack Capacity

- 1000 kg

- Lifting Speed

- Approx. 50 mm per second

- Condition

- New

- Lifting Capacity

- 1000 kg

- Max. Lifting Load

- 1000 kg

- Max. Lifting Height

- 1600 mm

- Power Source

- Manual

- Power Consumption

- Manual

- Voltage

- Manual Operation (No Voltage Required)

- Feature

- Ergonomic design, durable powder coated finish

- Attributes

- Robust construction, Easy operation

- Brake Type

- Foot Brake

- Net Weight

- Approx. 220 kg

- Fork Width (Adjustable)

- 300-740 mm

- Overall Height

- 1990 mm

- Fork Length

- 900 mm

- Lowered Fork Height

- 90 mm

- Mast Material

- High Quality Steel

- Overall Width

- 850 mm

- Finish

- Powder Coated

Lift Stacker Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Lift Stacker

We are the manufacturer of Lift Stacker with low maintenance, cost effective material handling equipment which is used in production areas for loading / unloading material Hydraulic bag Stacker are basically used for Bulk Material Handling Operations and Intensive Multi shift Operations. They are known for their durability, pollution free functioning, capacity of bearing heavy loads, safe operations and resistance to rust, scratches or wear.

Reliable and Robust Manual Lift Stacker

Constructed from high-quality steel and finished with a durable powder coating, this manual lift stacker offers exceptional strength and corrosion resistance. Designed to meet rigorous industrial requirements, its robust build ensures long-lasting performance while maintaining ease of use and low maintenance demands.

Adaptable for Multiple Applications

With adjustable forks spanning 300 to 740 mm and a compact overall width of 850 mm, the stacker fits seamlessly in various warehouse and storage environments. Its fixed mast and ergonomic handle make it highly maneuverable, while the foot-operated brake adds an extra layer of safety during operation.

FAQs of Lift Stacker:

Q: How do I operate the manual lift stacker?

A: To operate the stacker, simply use the ergonomic push handle to maneuver the equipment. Lifting and lowering are controlled via a manual hydraulic systemno external power source is needed. To secure the load during use, engage the foot brake located at the base.Q: What is the maximum lifting height and load capacity of this stacker?

A: This manual lift stacker can lift loads up to 1000 kg and reach a maximum lifting height of 1600 mm, making it suitable for a wide range of warehouse tasks.Q: Where is this manual lift stacker suitable for use?

A: The stacker is ideal for warehouses, manufacturing facilities, distribution centers, and storage areas where compact, efficient, and manual material handling equipment is required.Q: What is the process for adjusting the fork width?

A: The fork width can be manually adjusted from 300 mm to 740 mm, allowing you to accommodate different pallet and load sizes as needed. Simply release the fork locking mechanism, set your desired width, and re-secure the lock.Q: What are the key benefits of using this manual lift stacker?

A: Benefits include robust construction, ergonomic operation, adjustable forks for versatility, durable powder-coated finish, and low maintenance. It operates without electricity, reducing operating costs and offering flexibility for various locations.Q: When should the manual lift stacker be serviced?

A: For optimal performance, inspect the stacker regularly for any signs of wear or damage. Lubricate moving parts as needed and check hydraulic fluid levels, following the manufacturers maintenance guidelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Stacker Category

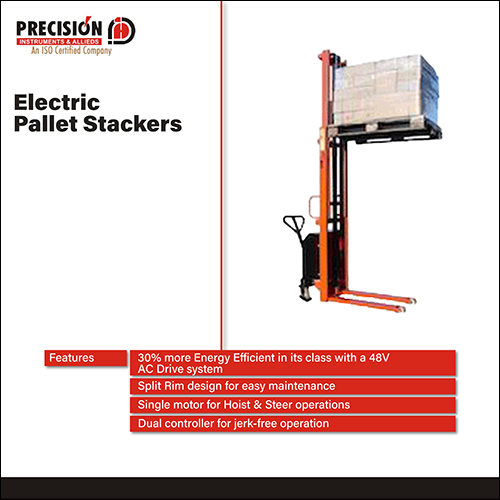

Electric Pallet Stacker

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Emergency Stop Button, Compact Design, Maintenance Free Battery

Condition : New

Equipment Type : Electric Pallet Stacker

Counter Balance Stacker

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Userfriendly Operation, Low Maintenance

Condition : New

Equipment Type : Industrial Material Handling

Fork Stacker

Price 50000-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Easy Operation, Compact Design

Condition : New

Equipment Type : Fork Stacker

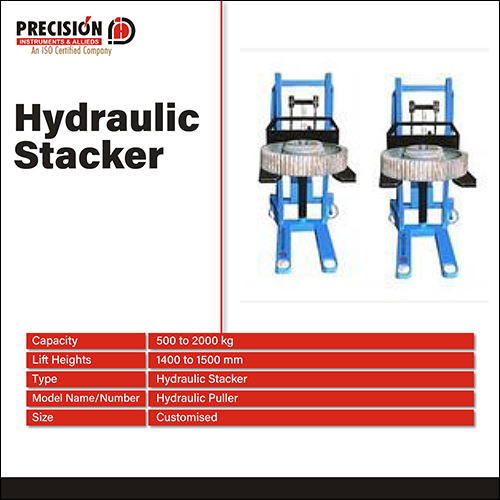

Industrial Hydraulic Stackers

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust Construction, Compact Design

Condition : New

Equipment Type : Industrial Hydraulic Stacker

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free