PIH 2004

MOQ : 1 Piece

PIH 2004 Specification

- Rated Frequency

- 50Hz

- Voltage

- 220V 10% / 50Hz

- Type

- High Frequency Induction Heater

- Material

- Metal housing, copper coil

- Application

- Industrial hardening, soldering, forging, brazing, melting

- Max. Input Power

- 20 KW

- Max. Output Power

- 18 KW

- Oscillation Frequency

- 30~80 KHz

- Cooling Water Pressure

- 0.2-0.3 Mpa

- Host Weight

- 42 KG

- Transformer Weight

- 36 KG

- Temperature Protection

- Yes

- Water Flow Rate

- 10L/min

- Control Mode

- Digital/Analog

- Dimension (Transformer)

- 430215370mm

- Duty Cycle

- 100%

- Dimension (Host)

- 590260500mm

PIH 2004 Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About PIH 2004

The PIH 2004 High Frequency Induction Heater is highly recommended for industrial needs demanding peerless performance and reliability. This top-rated solution is designed for hardening, soldering, forging, brazing, and melting, boasting an astonishing 100% duty cycle and a water flow rate of 10L/min for unmatched cooling. With a digital/analog control mode and robust metal housing with copper coil, it ensures unparalleled operation. Explore exceptional efficiency with a 20 KW input and 18 KW output power. As a leading exporter, manufacturer, and supplier in India, we deliver the industrys finest.

Unmatched Features and Durable Construction

The PIH 2004 offers superior functionality with its high-frequency operation (30~80 KHz), rugged metal housing, and efficient copper coil technology. Designed for applications such as industrial hardening, forging, brazing, melting, and soldering, it is suitable for a wide range of manufacturing settings. Its digital/analog controls ensure flexible, precise operation, while integrated temperature protection and optimal water cooling guarantee safe and continuous use without compromise.

Domestic Market, Shipping, and Sample Policy

Our PIH 2004 enjoys great demand across the main domestic market, where it is delivered securely within India. We offer reliable transport services to ensure your machine is shipped with utmost care and in robust packaging. Sample requests follow a dedicated policy to support your evaluation needs. Each unit is safely packed for protection during transit, ensuring the PIH 2004 arrives in pristine condition wherever you need it.

Unmatched Features and Durable Construction

The PIH 2004 offers superior functionality with its high-frequency operation (30~80 KHz), rugged metal housing, and efficient copper coil technology. Designed for applications such as industrial hardening, forging, brazing, melting, and soldering, it is suitable for a wide range of manufacturing settings. Its digital/analog controls ensure flexible, precise operation, while integrated temperature protection and optimal water cooling guarantee safe and continuous use without compromise.

Domestic Market, Shipping, and Sample Policy

Our PIH 2004 enjoys great demand across the main domestic market, where it is delivered securely within India. We offer reliable transport services to ensure your machine is shipped with utmost care and in robust packaging. Sample requests follow a dedicated policy to support your evaluation needs. Each unit is safely packed for protection during transit, ensuring the PIH 2004 arrives in pristine condition wherever you need it.

FAQs of PIH 2004:

Q: How does the PIH 2004 High Frequency Induction Heater benefit industrial applications?

A: The PIH 2004 delivers consistent results in hardening, soldering, forging, brazing, and melting thanks to its continuous 100% duty cycle and advanced cooling system, ensuring efficiency and longevity in demanding environments.Q: What control modes are available for operating the machine?

A: The PIH 2004 supports both digital and analog control modes, giving operators the flexibility to choose the most suitable method for specific applications and ensuring precise operation.Q: Where can this induction heater be effectively used?

A: This model is ideal for industrial settings requiring rapid heatingsuch as metalworkshops, manufacturing plants, and facilities involved in heat treatment, forging, and soldering processes.Q: What process is required to get a sample of the PIH 2004?

A: Sample requests can be submitted through our sample policy. Please contact our sales team to initiate the process and discuss the evaluation requirements.Q: When is the PIH 2004 shipped after placing an order?

A: Once your order is confirmed, the PIH 2004 is packed with care and shipped promptly using trusted transport services, ensuring timely and safe delivery to your location.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Other Category

PIH 2001 SAA Red

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel / Plastic

Voltage : 220V

Type : PIH 2001 SAA Red

PIH 2004 SPL Back Side

Price Range 50000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Voltage : 220 V

Type : Induction Heater

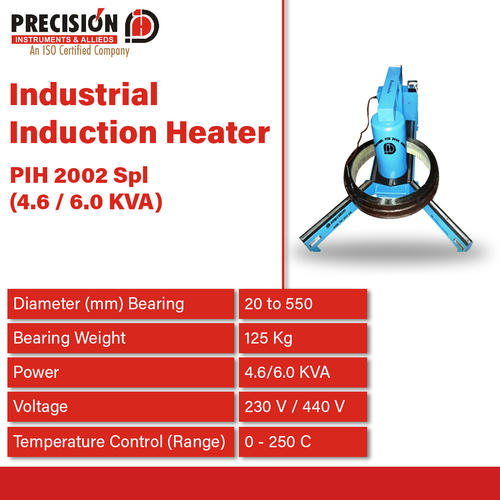

Industrial Induction Heaater PIH 2002 SPl 4.6 6.o KVA

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Voltage : 220440 Volt (v)

Type : Induction Heater

Industrial Induction Heaater PIH 2002 SPl (2.0 / 2.6 KVA)

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Voltage : 220 Volt (v)

Type : Induction Heaater

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS